As consumer trends continue to shift, the beverage industry is undergoing a transformation in packaging. From the rapidly rising popularity of RTD cocktails to eco-friendly wine and small-volume spirits packaging. Beverage brands are experimenting with alcohol packaging that meets consumer needs while adapting quickly to market demands. While traditional packaging is a classic, it is increasingly showing disadvantages in terms of shipping, carbon footprint, and cost.

Spout Pouch is an innovative packaging method based on the stand-up pouch design. Its key features are portability, safety, and environment. Its lightweight packaging and minimal material requirements make this emerging drink bag a sustainable alternative for the alcoholic beverage market.

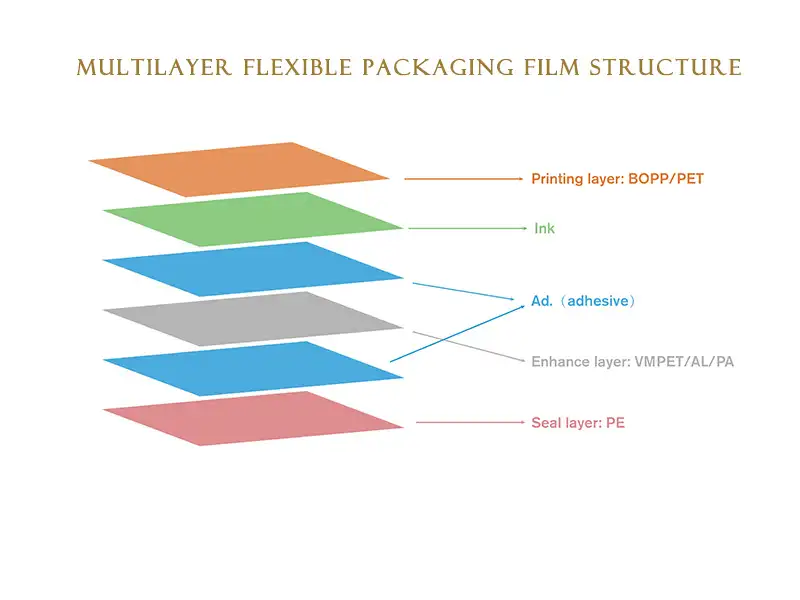

Stand-up Pouch with Spout Packaging Structure

Flexible packaging typically features a multi-layer film composite structure, based on core requirements such as sealing, load-bearing capacity, and printing. The overall structure consists of a spout and doypack. Spouts primarily provide ease of sucking, pouring, and repeated sealing, and are primarily made of food-grade plastic. PP/PE materials are commonly used with silicone/rubber seals to enhance sealing performance, prevent leaks, and facilitate short-term storage after opening.

Stand-up bag is the main body of the spout pouch. The packaging materials are a printing layer, a functional layer, and a heat-seal layer. The printing layer's core function is to carry the printed pattern, ensure ink adhesion, and protect the inner layer with abrasion resistance. The functional layer, also known as the barrier layer, provides high oxygen resistance, moisture protection, and light shielding, with a certain degree of puncture resistance. The heat-seal layer, which comes into direct contact with the contents, is safe, non-toxic, and flexible, made from a food-grade film material.

The Importance of Liquid Drink Pouch in Sustainability

Compared to traditional glass bottles, spout pouches are up to 90% lighter, meaning more product can be loaded onto each truck during shipping. The lightweight bag remarkably reduces fuel consumption and carbon emissions, bringing environmental benefits to the earth that traditional packaging cannot achieve. Nowadays, alcohol pouches can be made from mono-material recyclable materials such as PE or PP, and have a much lower carbon footprint than traditional bottles or cans. Liquor flexible packaging is strong, multi-layered and abrasion resistant. Easy shipping, low breakage rate of glass bottles. Food grade materials are safer and leak-resistant. Naturally, the spout pouch can be used as an alternative or additional packaging, which is suitable for small and medium-sized brands.

Advantages of Customized Alcohol Beverage Spout Bags

- Low-cost of production

Unit price of spout bag is far lower than that of glass bottles or cans. Large-scale production (Our low MOQ is 500pcs) can be further reduced the unit price. Liquid pouch is lightweight and reducing logistics costs by 20-40% (DHL/FedEx data), and is especially suitable for e-commerce. Automated filling and sealing processes reduce labor costs, increase production speed and packaging efficiency.

- Lightweight and portability

The flexible design of the drink pouch is less than the weight of a bottle of mineral water. It is very suitable for outdoor, travel, party and other scenes, catering to the RTD (Ready-to-Drink) beverage consumption trend. With screw cap spout, easy to open and close, reusable. It’s a user-friendly single-serve beverage packaging (such as 100-250ml cocktail). The feature of flexible packaging is compressible, reducing the demand for storage and retail space. Merchants are less likely to accumulate goods, and consumers are more prefer it.

- Alcohol-safe and durable

Made of food-grade PET/NY/PE or EVOH composite materials, it is resistant to 15-43% ABV alcohol (such as cocktails and spirits), ensuring long-term storage (6-12 months) without leakage or odor. Spout pouch is resistant to extrusion, with a breakage rate of less than 1%, making it suitable for express delivery and long-distance shipping.

- Flexible customized printing

RTD spout pouch supports full-color CMYK printing or metallic effects to display brand logo and product story, enhancing shelf appeal. Wine pouch for liquor and wine gives traditional alcohol a modern, youthful image, appealing to millennials and Generation Z. All capacities can be customized to meet the needs of single or multiple people, achieving product diversification.

- Market adoption

Wine spout pouch with its portability, low cost and flexible design, perfectly fits the RTD market. The production cycle is short (5-7 days), making it suitable for rapid market response.

Spout Pouch Packaging Material Structure Analysis

The typical structure of a spout pouch is outer layer (printing layer) - adhesive - middle layer (barrier layer) - adhesive - inner layer (heat seal layer).

Printing layer material is usually PET or NY. PET has good printing adaptability, can make the color more vivid and durable, and has a certain stiffness and tensile resistance to protect the inner layer material safety.

Barrier layer materials are a crucial barrier for wine packaging, blocking oxygen and light. Barrier materials used include EVOH and aluminum foil. EVOH offers excellent oxygen barrier properties, slowing wine oxidation. Aluminum foil blocks both oxygen and light, making it suitable for packaging light-sensitive wines.

Heat seal layer ensures tightness and is resistant to alcohol corrosion. It’s usually made of food-grade PE material and can be in direct contact with alcoholic beverages. It prevents alcohol degradation and stratification, maintaining taste and safety.

Flexible Packaging Solutions for Different RTD Products

Transparent Material typical structure PET/NY/PE or PET/EVOH-PE. The material is highly transparent, the texture is clear, and the contents can be seen directly. The liquid color is displayed through the bag, which is visually refreshing and increases the desire to buy. Suitable for music festival activities, high-value mixed cocktail drink pouches.

High-barrier material structures include PET/AL/NY/PE or PET/AL/PE. These can effectively block oxygen, water vapor, and ultraviolet rays, to extending the shelf life of products. Aluminum film printing packaging can enhance brand perception. It is the ideal packaging material for alcoholic RTD (pre-mixed drinks, cocktails, wine, beer, premium spirits).

Recyclable Material typical structure is food-grade PE/PE mono-material. Complies with sustainable packaging regulations in the European and American markets and is the preferred choice for environmental trends. Some low-alcohol beverages (hard seltzer, cocktails, fruit wine) can be packaged in this material.

Portable Drink Packaging is the Flexible Choice for Alcohol Brand and Retailer

Beverage volumes from 50ml to 5L can be customized to meet your needs, from single bags to family packs. These include small-capacity portable drink packaging (50ml-500ml), medium-capacity drink share bags (500ml-1L), and large-capacity retail alcohol pouches (2L-5L), catering to diverse brand needs.

Digital printing offers flexibility and customization. No platemaking required, reducing costs and time, while delivering high-quality printing. This allows brands to quickly respond to market demands by launching co-branded products and festival packaging. It supports small batch orders, making it more suitable for new product launches and small businesses, reducing the risk of stockpiling.

Spout pouch alcohol packaging solves the shipping and delivery pain points faced by e-commerce and retail retailers. For e-commerce brands, alcohol pouch packaging and storage costs are reduced, while the packaging integrity enhances the consumer delivery experience. In retail channels, the novel design and small-volume packaging format are more appealing to young consumers and those seeking early adopters. It reduces supply chain costs, complies with environmental regulations, and helps brands attract consumers who value low-carbon packaging.

The travel-friendly wine packaging pouch is lightweight and requires minimal raw materials, reducing the depletion of Earth's resources and carbon emissions. For retailers, this offers the dual benefits of increased profit margins and meeting sustainability goals.

Alcohol drink pouches are more than just a packaging shift. They represent a significant step toward increasing environmental awareness and reducing carbon footprints. Breaking free from the limitations of traditional glass bottles, they offer lightweight, shatterproof, portable, and low-cost advantages, enabling brands to enter the market more efficiently. By transitioning from rigid to flexible packaging, brands demonstrate social responsibility and resonate with consumers. Whether you're an RTD cocktail brand, a startup, or a liquor company seeking sustainable alternatives, spout pouches can help you flexibly adapt to market changes. If interested, please contact us for the latest quote.