The coffee market is expected to reach US$96.45 billion in 2025 in terms of at-home consumption (revenue generated in supermarkets and convenience stores) In such a large market, how can coffee companies stand out? In order to ensure the freshness of coffee beans, the oxygen barrier properties and light barrier properties of the coffee packaging must be carefully considered. Usually, aluminum foil and metallized film, that is VMPET (Vacuum Metalized PET) are considered better coffee pouches materials.

So, what do they have in common and what are their differences?

Commonalities

First, let’s go with OTR and WVTR, which are effective assessments of coffee packaging material quality.

Oxygen transmission rate (OTR)

OTR is the volume of oxygen that passes through a material over a given period of time, usually expressed as milliliters per square meter per day at standard temperature and pressure (mL/m²/24h at STP). It is of great importance in the packaging of processed foods and it is critical that headspace oxygen is excluded (Kumar, 1994).

Water Vapor Transmission Rate (WVTR)

Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance. It is a measure of the permeability for vapor barriers. Moisture sensitive foods and pharmaceuticals are put in packaging with controlled MVTR to achieve the required quality, safety, and shelf life.

| Parameters (N=51) | Aluminum (un-flexed) | MPET (un-flexed) |

| OTR | 0.06571 | 0.2283 |

| WVTR | 0.00873 | 0.21408 |

*Optimal barrier properties of Aluminium and MPET (un-flexed) under 180 day shelf life

The European and American markets have requirements for the barrier properties of coffee packaging (such as oxygen permeability <1cm³/(m²・24h・0.1MPa) and water vapor permeability <1g/(m²・24h)), which directly affect the shelf life of coffee beans (flavor loss must be <5% within a shelf life of 6-12 months).

In summary, aluminum and MPET(VMPET) both have almost zero Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR), making it an excellent barrier against external elements.

Differences

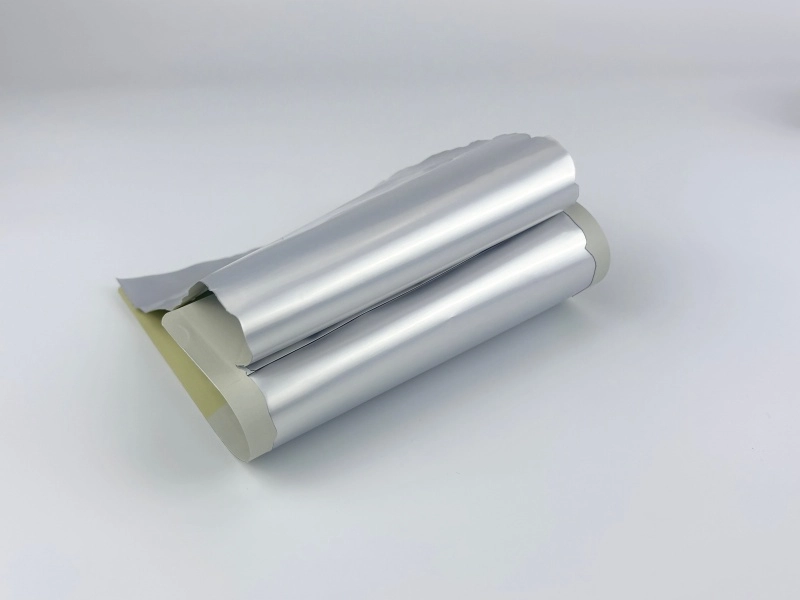

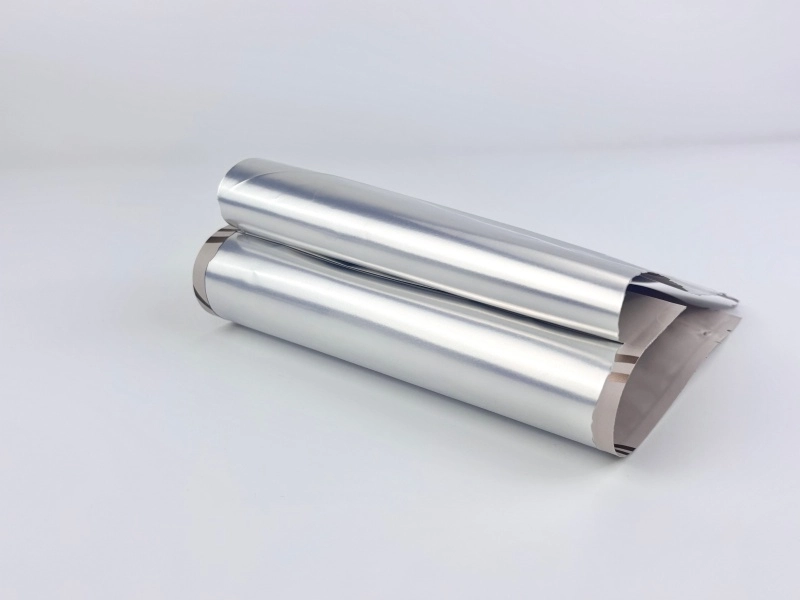

Appearance

Aluminum: has a matte property, and when the outermost layer is PE, it presents a matte effect. Some customers like the matte effect because the bag looks more advanced and has a better texture.

VMPET: has the characteristic of being glossy effect. Light reflectivity up to 97%, and if the outermost layer is PE, the packaging surface will be shiny and reflective. The shiny bag will be more dazzling and make the packaging more eye-catching.

Cost

Aluminum: the cost of coffee bags made of pure aluminum foil is relatively high. Pure aluminum foil has best barrier properties and can effectively prevent oxygen, moisture and UV-light. It is a good choice for companies with sufficient budget or pursuing high-quality gourmet coffee beans.

VMPET: is aluminized film, which is a composite material formed by coating a very thin layer of metal aluminum on the surface of a plastic film. Its base material is a polyester film (PET), and the cost is relatively low. In addition, the metallized film process can greatly reduce the amount of aluminum used. Compared with pure aluminum foil, the aluminum consumption of VMPET is about 1/140-1/180 of that of aluminum foil, thus reducing the cost.

So, in the case of equal area, the material cost of VMPET is 70% or even 50% of pure aluminum.

Recyclability

Can aluminum foil be recycled? This is a question that many people are concerned about.

Aluminum: The recycling process is relatively simple. When pure aluminum is recycled, it only needs to go through routine steps such as sorting, cleaning, crushing, and smelting to be made into new aluminum products.

VMPET: Recycling is difficult. VMPET is a composite material formed by coating a very thin layer of metal aluminum on the surface of a polyester film. When recycling, the metal aluminum and the polyester film must be separated first, which increases the complexity and cost of recycling. At present, chemical recycling or physical recycling methods are usually used for the recycling of VMPET, but these methods have certain technical difficulties and high costs.In some places, VMPET is treated as ordinary garbage and is not effectively recycled.

Understanding the characteristics and differences of packaging materials and choosing the most suitable packaging can make your business more successful! Contact us now to get a quote for different material!