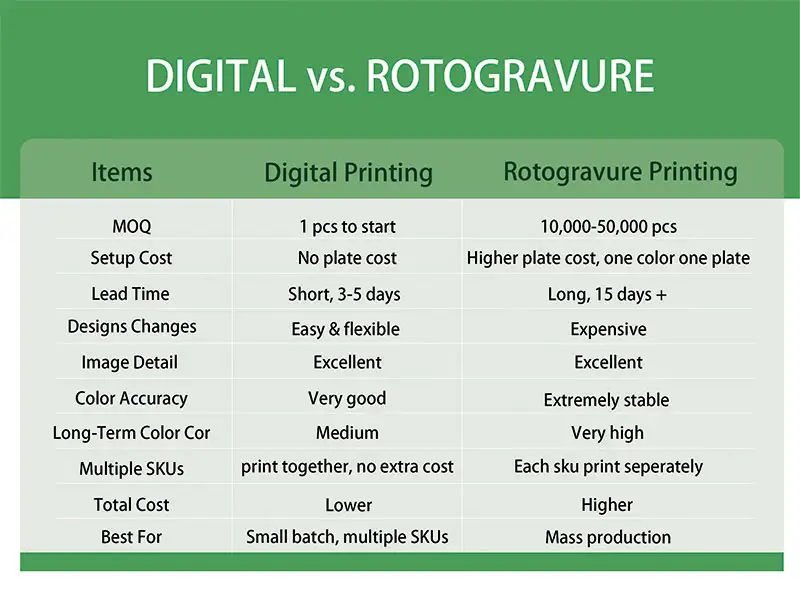

Choosing the right printing method is one of the most important decisions when developing custom flexible packaging.

For brands considering custom pouches, digital printing and rotogravure printing are the two most common options — but they serve very different business needs.

This article compares digital printing vs rotogravure printing for pouches in terms of cost, minimum order quantity (MOQ), lead time, and ideal use cases, helping you decide which solution fits your brand best.

What Is Digital Printing for Flexible Packaging?

Digital printing for pouches is a modern printing method that transfers artwork directly from digital files to the packaging film without printing plates.

Key characteristics of digital printing:

-

No plate-making cost

-

Ideal for small to medium order quantities

-

Fast setup and short production lead time

-

Easy design changes between batches

Digital printing is especially popular for custom pouches, seasonal designs, multiple SKUs, and market testing.

What Is Rotogravure Printing?

Rotogravure printing is a traditional printing method that uses engraved metal cylinders to transfer ink onto packaging films.

Key characteristics of rotogravure printing:

-

High initial setup cost due to cylinders

-

Very low unit cost at large volumes

-

Extremely consistent color reproduction

-

Best suited for long-term, high-volume production

Because of the high cylinder cost, rotogravure printing usually requires very high MOQs to be cost-effective.

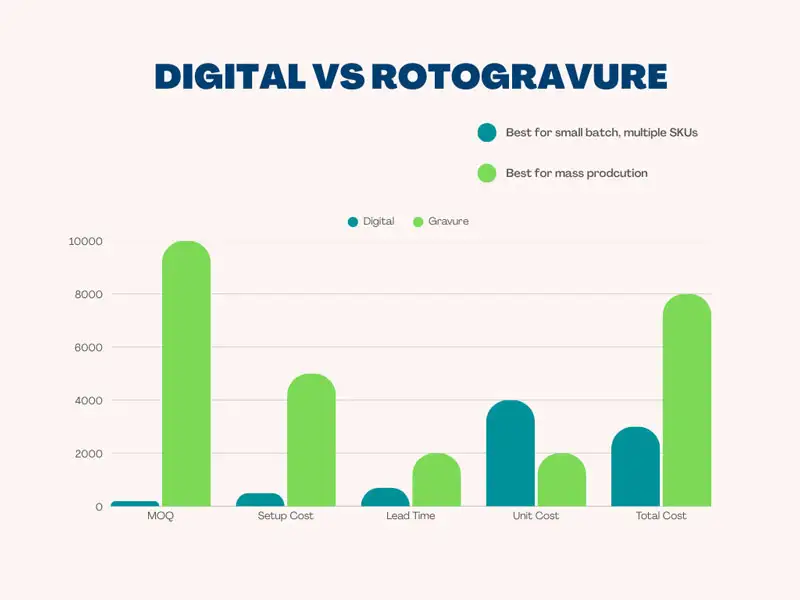

Digital Printing vs Rotogravure: Cost Comparison

Cost structure is where the two methods differ most.

Digital printing costs

-

No plate or cylinder fees

-

Slightly higher unit price

-

Lower total investment for small batches

Rotogravure printing costs

-

High upfront cylinder cost

-

Lower unit price at large volumes

-

High financial risk for small or changing orders

For small and medium brands, digital printing often results in lower total packaging cost, even if the per-unit price is higher.

MOQ Differences Between Digital and Gravure Printing

Minimum order quantity (MOQ) is a critical factor for many brands.

Typical MOQs:

-

Digital printed pouches: 500–5,000 pcs

-

Rotogravure printed pouches: 20,000–100,000+ pcs

Digital printing allows brands to:

-

Launch new products with low risk

-

Test multiple designs or flavors

-

Avoid excess inventory and waste

This flexibility makes digital printing ideal for startups, SMEs, and brands with frequent design updates.

Lead Time and Production Flexibility

Lead time can directly impact your go-to-market speed.

Digital printing

-

No plate preparation

-

Faster proofing and approval

-

Typical lead time: 2–4 weeks

Rotogravure printing

-

Cylinder production required

-

Longer setup and approval process

-

Typical lead time: 6–10 weeks

For brands that value speed and responsiveness, digital printing offers a clear advantage.

When Digital Printed Pouches Are the Better Choice

Digital printed pouches are the better option if you:

-

Need low MOQ packaging

-

Launch new or seasonal products

-

Offer multiple SKUs or limited editions

-

Want faster production and delivery

-

Prefer flexible design changes

Many brands choose digital printed pouches to reduce risk while maintaining high-quality packaging appearance.

When Rotogravure Printing Still Makes Sense

Rotogravure printing may be the better choice if you:

-

Produce very large volumes consistently

-

Use the same design for long periods

-

Focus on minimizing unit cost at scale

-

Have stable demand forecasts

For established brands with high-volume SKUs, gravure printing can still be a cost-effective solution.

Final Recommendation for Brands and Importers

There is no single “best” printing method for all brands.

-

Digital printing is best for flexibility, low MOQ, fast turnaround, and reduced financial risk.

-

Rotogravure printing is best for large-scale, long-term production with stable designs.

If you are unsure which option fits your product, starting with digital printing allows you to test the market before committing to high-volume production.

Digital Printing vs Rotogravure Printing: Quick FAQs

Is digital printing quality as good as gravure printing?

Yes. Modern digital printing offers excellent color accuracy and sharp details suitable for premium packaging.

Are digital printed pouches more expensive?

Per unit, yes. But total project cost is often lower due to low MOQ and no plate fees.

Can I switch from digital printing to gravure later?

Absolutely. Many brands start with digital printing and move to gravure once volumes increase.