1. The Rise of Fresh & Raw Pet Food

In 2025, the fresh pet food and raw feeding BARF (Biologically Appropriate Raw Food Diet) category has become the fastest-growing segm ent of the industry. Pet owners are shifting away from traditional kibble and canned foods, instead prioritizing nutrient-rich, minimally processed, raw-inspired diets that resemble what pets would naturally eat. This surge is powered by rising awareness of pet wellness, increased trust in human-grade ingredients, and the booming popularity of subscription-based fresh meals and frozen raw diets. As a result, brands are rapidly innovating in cold chain logistics, single-serve packaging, and durable frozen food packaging to meet demand. As fresh and raw (BARF) pet food becomes the fastest-growing category in 2025, frozen bag for food plays a critical role in maintaining product safety, freshness, and nutritional integrity. And it requires low temperatures for safe storage and to preserve nutrients.

2. Bag Material - Kibble Packaging VS. Fresh Pet Food Packaging

- Kibble Packaging Material - OPP/VMPET/PE

Dry kibble requires pet food packaging that protects against oxygen, moisture, pests, and aroma loss. One of the most common material used in the pet food industry is the multi-layer laminate OPP/VMPET/PE. Each layer serves a specific function to preserve freshness and extend shelf life. These bags usually perform well at room temperature but become brittle and crack freezer temperatures (-18°C and below).

- Fresh Pet Food Packaging Material - PA/Frozen PE (Nylon/Frozen PE)

Our frozen safe food-grade materials are passes the test for freezing stability, oxygen and moisture barrier performance, and migration safety under food-contact regulations.

- Nylon (PA): Provides puncture resistance (crucial for bone-in meat). Puncture Resistance (The "Bone" Factor): Many raw diets include ground bone. Mention that you can add a Nylon (NY/PA) layer to your flat bags. Nylon is tough and prevents sharp bone fragments from piercing the bag from the inside.

- Modified Frozen PE: Remains flexible, soft and maintains strong seal integrity even at -25°C. It is a specialized low-temperature-resistant polyethylene blend designed specifically for frozen food applications. It significantly outperforms standard PE used in regular kibble or ambient packaging.

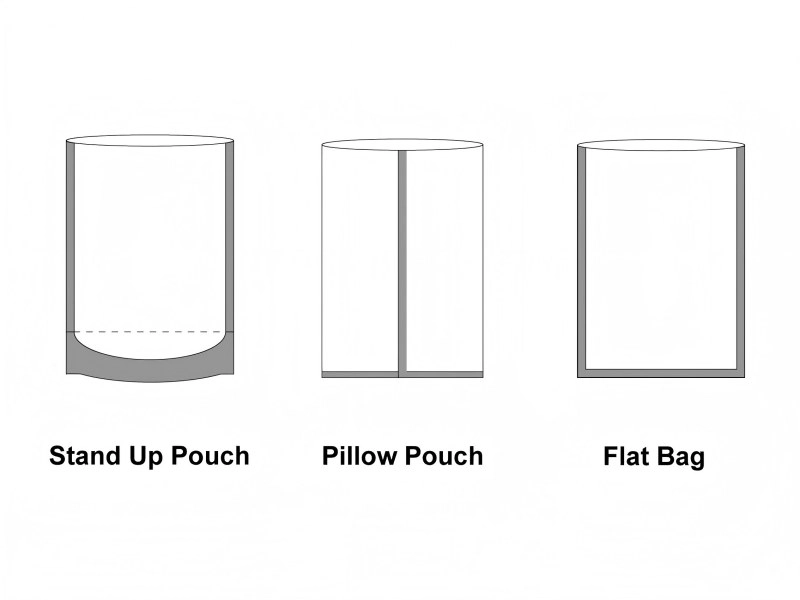

3. Bag Type - Stand Up Pouch & Pillow Pouch VS. Flat Bag

- Stand up pouches may let the food gets stuck at the bottom when the raw food is thawed.

- Pillow Pouch that have a back seal which may leak raw juices when under stress during transport.

- Flat bag offers a seamless, leak-proof face perfect for vacuum sealing and ruined brand reputation.

4. Custom Printed Flat Pouches: Leading 2025, Booming in 2026

- Custom frozen food packaging is not just a trend:

- It is becoming the industry standard for fresh, raw, and frozen pet food.

- It is leading packaging demand in 2025.

- It will become even more dominant in 2026 as fresh pet food expands globally.

- How we GAOAOG bring advantages to start-up companies?

- MOQ 500 pcs

- Manual samples

- 5-day production

- Frozen-safe: pass the safety test for -18 degrees C (-0.4 degrees F)

- Custom sizes & printing effect (matte & glossy ) & vacuum material option

5. Contact our team for Raw Dog Food Packaging Consultation